Range Overview

From Alfa Romeo through to Volvo, there's and Adrad aftermarket radiator, intercooler or oil cooler to suit your vehicle.

Adrad stocks Australia's largest range of automotive radiators including locally manufactured and imported units. Thousands of parts are readily available from a national network of warehouses, so the right part for your vehicle is never far away.

QUALITY PARTS

Adrad cooling products are sourced from both original equipment and quality accredited aftermarket partners. All Adrad supplied product is tested to the highest quality standards to ensuring trouble free motoring.

NATIONAL SUPPORT

With a network of branch offices and distribution warehouses located all across Australia, Adrad provides exceptional product support and service.

KNOWLEDGE & EXPERIENCE

The Adrad group of companies includes radiator businesses that date back to the 1920's as well as modern manufacturing facilities operating at the cutting edge of world-wide heat exchange technology.

This extensive knowledge and experience is reflected in the products developed and chosen for your vehicle.

At ADRAD we are proud to be able to supply off the- shelf and made-to-order complete aluminium radiator assemblies. These units are designed and manufactured to ensure optimal performance, durability, appearance and ease of fitment.

Adrad has hundreds of performance cooling radiators, intercoolers and oil coolers. If your particular vehicle is not listed, we can manufacture a performance aluminium radiator to suit it. All we require is a sample or a detailed drawing.

Our three most common aluminium radiator core thicknesses are 38mm, 56mm, and 73mm.

TECHNOLOGY

HEMMED FIN

Adrad Australian made alloy radiators feature a hemmed fin. The edge of the fin is turned back on itself to double the thickness of the metal, adding strength to the face of the core for durability.

STEPPED CORES

Stepped cores are available in a number of configurations. Stepped cores enable air to flow freely through the core due to their unique angled design.

Distinctive radiator designs are a key feature on many vintage and veteran vehicles, restorers often require genuine honeycomb or cellular replacement radiator cores in order to maintain the integrity and value of their special vehicle.

Fortunately, there is no need to sacrifice accurate styling or quality of construction in the quest for reliable cooling performance.

ADRAD manufactures honeycomb and cellular cores. ADRAD craftsmen build each bespoke radiator core employing authentic construction techniques. Each core is handmade with accurate styling, quality construction and reliable cooling performance.

High quality copper and brass strip is fed into original machinery from the period, transforming it into beautifully detailed radiator cores that are designed to last.

After shaping and solder coating has been completed, the new core is ready for the tanks and supports to be fitted.

CORE PROFILES

HEXAGON PROFILE

HEXAGON PROFILE

Exact reproduction 5/16" Honeycomb Radiator cores are produced on original equipment and are handmade.

The period-correct look for many veteran and vintage vehicles.

CELLULAR PROFILE

CELLULAR PROFILE

Cellular radiator cores and produced on original equipment

are handmade, to capture the period-correct look for your vehicles radiator.

CORE SHAPE CHART

Below is our radiator core shape chart showing you the options available.

Adrad's on-highway cooling products include radiators, charge air coolers and oil coolers that we build in our four Australian manufacturing plants. By varying materials, fin pitch, tubes and other components,

Adrad can manufacture the same size radiator over 10,000 different ways.

This means that Adrad cooling products can be specifically configured to meet the particular needs for your vehicle, your location and workload.

TECHNOLOGY

ULTRA-T

Adrad Ultra-T radiator cores fit a higher number of tubes into a compact width to deliver extra cooling power without using an extra thick core.

ADFUSE

Adrad Adfuse cores feature precision welded headers to create radiator cores with extreme strength and durability.

Adfuse is exclusive to Adrad and is ideal for heavy vehicles that endure harsh vibration, torsion stress, and extreme cycling pressures and temperatures.

ULTRA SEAL

The patented silicone grommet system in these charge air coolers eliminates the solid join between the core and manifolds. As a result, the unit is highly resilient against thermal expansion and contraction that can cause leaks in standard charge air coolers.

STAY COOL & SAVE

Adrad has a range of high performance and efficient cooling options for hard working trucks, buses and other on-highway vehicles.

It is common to hear reports back from truck operators who are impressed with the thousands of dollars in fuel savings gained after having had an Adrad high performance radiator installed

Adrad has many innovative cooling solutions to ensure that equipment operating in the earthmoving, mining, power generation, rail, materials handling, marine and agricultural sectors remains working more efficiently for longer periods.

The result of these developments for the operator is greater efficiency, less down time which in turn equates to savings and greater profitability for the vehicle or equipment operator.

TECHNOLOGY

ADSHIELD

The Adshield core has been designed to combat sand blasting in earthmoving machinery - a problem that many equipment operators encounter that greatly reduces the efficiency and operating life of conventionally built radiators.

MECHANICALLY BONDED

Featuring heavy gauge materials and thick plate steel headers, Adrad mechanically bonded industrial radiators are designed to deliver super heavy duty cooling for large and powerful machinery including locomotive engines.

FIN FACING

Copper, brass or steel folded over the fin edge makes it super strong and corrosion resistant. This will provide significantly longer life in applications that are hard on cooling fins.

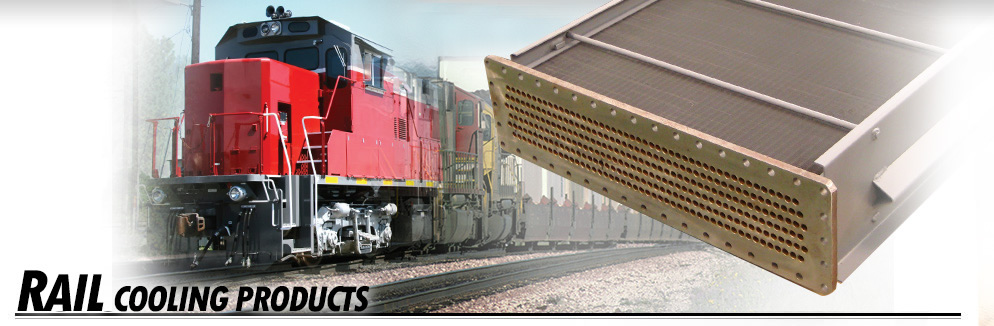

Locomotive cooling units operate under the combined stresses of prolonged high heat load, corrosion and vibration. ADRAD offers extreme heavy duty radiators that use a specialised construction method and heavy gauge headers to provide cooling for this application.

High quality and robust construction provides a long service life and minimal down time which is critical for rail transport operators.

TECHNOLOGY

MECHANICALLY BONDED RADIATORS

Mechanically Bonded radiator cores are ideal for super heavy duty cooling applications such as locomotive engines.

Extremely strong tube-to-header construction is combined thick-walled brass tube for maximum strength and reliability.

These cores withstand high pressure, vibration and thermal cycling over a long service life. Exceptional durability combines with high corrosion resistance for vastly reduced maintenance.

HEADER PLATES

Available in 16mm mild steel refer to table for min and maximum size configurations.

Adrad manufactures and supplies cooling products for tractors, harvesters and a variety of agricultural machinery. Cooling solutions for farm machines often requires addressing a variety of challenging environmental conditions.

Airborne dust, chaff or even feathers can rapidly clog a regular radiator core, so Adrad has design options that provide effective cooling in these unique conditions.

TECHNOLOGY

UNLOUVRED BRASS

Preventing debris from entering the radiator may not be practical, but building a radiator that allows material to pass through can be the solution. Adrad's unlouvred brass core is strong,

corrosion resistant and the smooth fin surface allows material to pass through the radiator as air is drawn through it or when being pressure-cleaned.

SOLDER COATED

Vehicles that operating in corrosive environments can benefit from a radiator made using solder-coated fin material. The solder adds an extra layer of protection to the fin, extending the service life of the radiator.

Cooling systems for power generation units typically must tolerate a remote location with harsh extremes of weather and a relentless operating cycle. For many years,

Adrad has been providing exceptionally strong and immensely reliable cooling systems that are proven performers in this unique and demanding application.

TECHNOLOGY

ADFUSE® - Adrad's Australian developed precision tube-to-header welding process for industrial radiators is the most advanced and sophisticated in Australia.

Welded joints provide superior strength and durability compared to soldered joints.

Our computer-controlled robot takes less than two seconds to complete each

tube-to-header weld with an accuracy of less than 0.1mm.

For even more strength, each ADFUSE® weld is also back-filled with solder to

provide extra support to each individual tube.

ADFUSE® produces a maximum strength bond able to better withstand the high temperatures and constant vibration that are found in demanding applications.